I didn't take any pictures today, but I should

have. There are a couple of small

(1" or less) air bubbles that have developed in the brake lines. We got down the oil pump can and filled it

with brake fluid. I used a large syringe

to a piece of tubing and used this apparatus to draw the brake fluid from the

reservoir in the engine compartment. I

attached the tubing from the oil pump to the right brake caliper bleeder valve,

opened the valve and began pumping. I

was able to push the bubbles out of the right brake system. Everything seems to be fine on the right

side. I attached the tubing to the left

brake caliper and opened the bleeder valve.

I began pumping and the bubbles began to move and then disappeared. The bubbles in the left system moved to the

co-pilot left master cylinder and entered

the cylinder. We stopped and

waited. Slowly the bubble began to come

back out of the cylinder. We tried

again. The same thing happened. Frustrated we decided to call it a day.

Friday, January 31, 2014

Wednesday, January 29, 2014

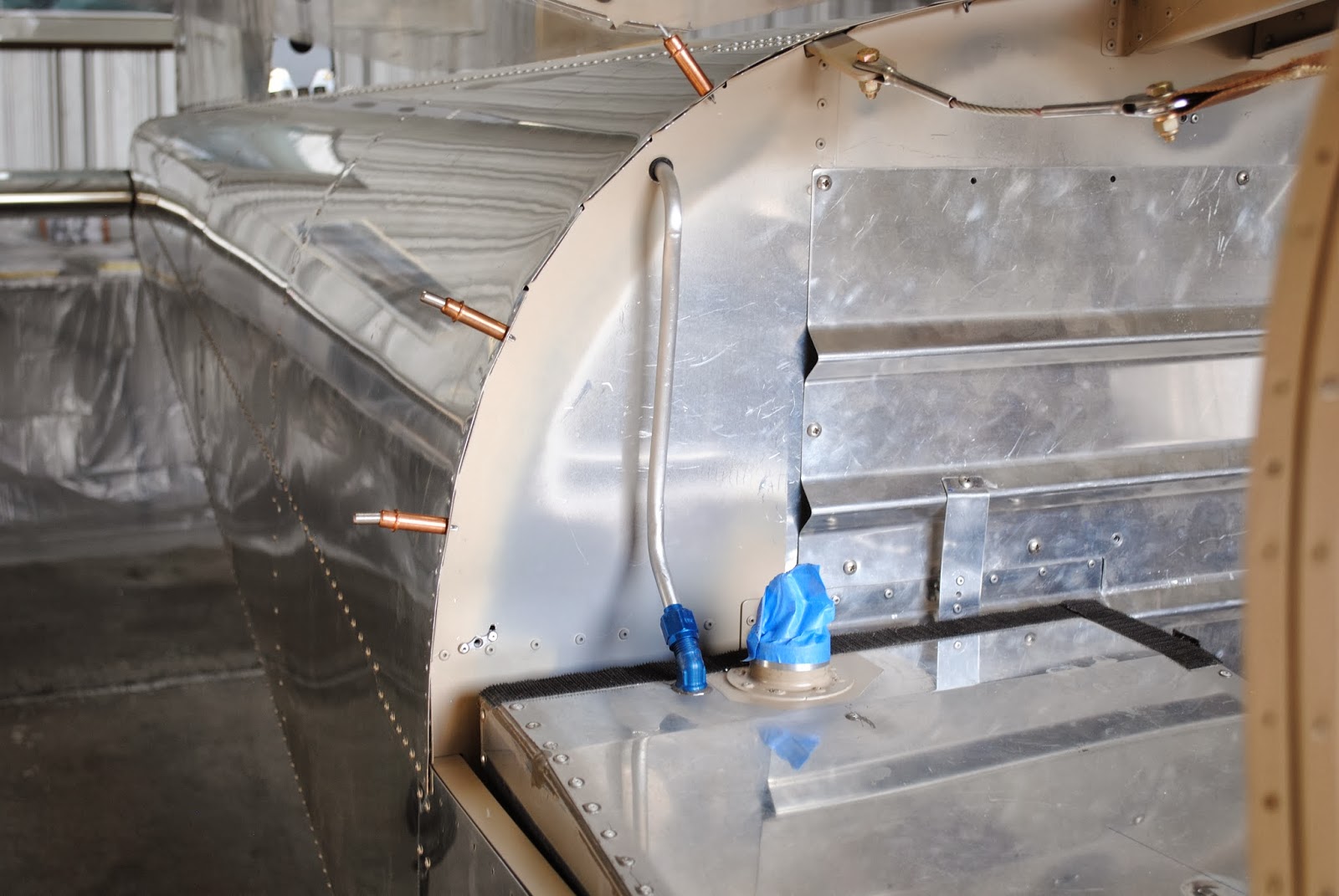

Baggage Upholstery Panel and New Fuel Vent

Today I reworked the right strap I attached

to the baggage bulkhead panel for the installation of the bulkhead upholstery

panel. I removed the small section of

the panel that is behind the fuel tank.

The modification is to allow access to the tail cone without removing

the fuel tank which must be done to remove the full sized panel. Because I installed a screw to attach the

strap to the stationary part of the panel I would have to remove the tank to

remove the screw in the strap which defeats the purpose of the removable

section of the access panel. I connected

the panels together and drilled out the rivet attaching the strap to the

removable section of the access panel. I

installed a nutplate in the access panel so that screw can be removed and the

removable part of the panel can be taken out.

I reinstalled the whole panel and then put the upholstered panel in

place. I was able to attach it with the

fasteners provided.

I drilled a hole in the upholstered panel for the new fuel tank

vent line. I also drilled a hole through

the bulkhead and installed a snap bushing.

I put the tank back into the airplane and then proceeded to make the

tubing section which goes from the tank fitting through the bulkhead. It took 3-times to make a tube that fits correctly. The first tube I made according to the

drawings and it was too short to reach the fitting on the fuel tank. I made another tube and after I clamped it

into the flaring tool I dropped the tool and badly kinked the tube. The third attempt was a success. I have a piece of tubing bent to the correct

configuration with a flared fitting on the right end. The other end passes through the

bulkhead. I will need to slot the

upholstered panel so I can slide it into place because once the tubing is

installed it cannot be removed from passing through the bulkhead. Now I need to make the tubing pieces which

are installed behind the bulkhead to vent the tank through the bottom of the

fuselage.

Monday, January 27, 2014

Baggage Bulkhead Upholstery

Today I spent a few hours working on the

baggage bulkhead upholstery attachment.

I decided to put four of the five screws to attach the upholstery panel

to the bulkhead along the bottom part of the panel.

Because the panel attaches to the flat of the bulkhead and also the

corrugated access panel to the tailcone area I decided to put in some attachment

straps. The straps go between 2-of the corrugations

in 2-places. First I attached the tailcone

access panel to the rear bulkhead. I cut

some straps out of some scrap material and bent them to fit the angle of the

corrugations. I drilled and clecoed the

strap to the left side of the access panel.

I then began working on the strap for the right

side of the panel. I cut and bent the

strap to fit the panel. I drilled,

clecoed and then riveted the right strap in place. After riveting the right strap I realized the

strap was riveted to the both stationary and permanent parts of the panel. I

will not be able to remove the panel if the strap is riveted to the permanent

portion the remains in place.

Accordingly I drilled out the rivet and installed a nutplate so the

strap can be removed with the access panel.

I had previously drilled the upholstered panel for the 5-attachment

screws and had transferred the location of the holes onto the straps and the surrounding

bulkhead.

I then proceeded to install nutplates on the straps. After attaching the nutplates to the straps I

drilled and installed nutplates on the flat bulkhead panels. Because holding the upholstered panel to the

bulkhead is not a structural challenge I opted to use an unorthodox method of

installing the nutplates. I drilled a ¼"

hole for the center of each nutplate. I

also drilled the holes in the ears of the nutplates to #30.

I then attached the nutplates to the forward

side of the bulkhead with the body of the nutplates through the ¼" holes. All 3-of these nutplates are installed with

LP-3 rivets. Because the upholstery

panel will be going over the corrugated panel and will not be laying flat I

decided it was not necessary to have the nutplates on the other side of the bulkhead or attach them

with flush head rivets. At this point I began to reinstall the removable

portion of the access panel and then realized the with the tank in place I will

not be able to remove the screw attaching the lower part of the right strap to

the permanent portion of the bulkhead cover.

What an idiot. Tomorrow I will

drill out the other rivet attaching the strap to the removable portion of the

access panel and install a nutplate there also.

That way I can remove the panel without removing the tank. Before leaving today I riveted the nutplates back onto the attachment points of the fuel tank.

Tomorrow will be a new day and I will once

again work on the bulkhead, the upholstery panel and see if I can finally get

it right. I am also working on a method

of reinforcing the panel to make the parts lineup correctly and present a flat

panel. Right now the panel sort of bends

in when it is screwed in place.

Friday, January 24, 2014

Fuel Tank Vent

Today I did some work towards the installation

of the new fuel tank vent system. I

removed the right turtle deck. I also

checked on the Pro-Seal installed a couple of days ago. It seems to be curing just fine. All of the rivets have been set. When I install the sender plate on the

forward end of the tank I will make sure all of the rivet heads have been

filled with Pro-Seal. I did a test fit

of the baggage area upholstery. The

vinyl covered part the installs above the fuel tank. I marked the location for the ½" diameter

hole that will be drilled through the upholstered bulkhead cover and the bulkhead.

I then decided to cash-it-in for the day.

I covered the cockpit area with some plastic

sheeting to keep the drips out.

Wednesday, January 22, 2014

Fuel Tank Modifications Continue

Today Tim went with me to the hangar. We worked on the fuel tank together. We mixed up a batch of Pro-Seal and started

installing some of the modification parts and pieces. First we installed the new vent fitting at

the rear of the tank. It was a challenge to get the fitting into the hole along

with Pro-seal and then get a retaining nut to tighten. I was able to get it on and it looks good

from the top and from the inside.

Next we tackled the installation of the

reinforcement plates in the forward corners.

I clecoed the plates in place and then we began to install the Cherry

Max rivets in the right front corner. What

a mess it made. We then installed the

plate in the left front corner. We

installed the Cherry Max rivets and then the 3-machine screws and nuts. We also replaced all of the blind rivets

along the bottom and edges of the tank.

All of the rivets and fasteners are installed

with Pro-Seal. The last thing we did was

install the Moller fuel gauge in the top of the tank. I will let it cure for a couple of days

before I do a final inside cleaning and install the sender plate on the forward

end. After I install the sender plate and let the Pro-Seal

cure for a few days I will retest for leaks.

My next efforts will be to fabricate and install the vent plumbing system

and the upholstery on the baggage compartment bulkhead.

Tuesday, January 21, 2014

Fuel Tank Mod Continue

Today I continued to work on the fuel

tank. I brought a ½" chisel from my

shop to help remove the Pro-Seal from the forward corners inside of the fuel

tank. It worked rather well. With the excess Pro-Seal removed I was able

to cleco the reinforcement plates to the tank corners. I clecoed the right corner plate to the tank

and drilled the required #30 holes. I

then moved the plate to the inside of the tank and final drilled the #19

holes. Because the mandrel was still

inside one of the rivets one of the holes is elongated. I will need to fill the hole with plenty of Pro-Seal

when I set the rivets. I then clecoed

the left corner plate in place inside of the tank. I am now ready to rivet these plates in place

and install new rivets in the additional drilled out locations.

I used a ScotchBrite wheel on my angle

grinder to buff the forward end of the tank and the sender plate so they are

ready to be Pro-Sealed in place. I

should have the tank reassembled in the next few days.

Monday, January 20, 2014

Fuel Tank, Stabilator Tips and Stuff

Today I worked on several things. I took the fuel tank back out to the

hangar. I also did a couple of other

things. I discovered that the switch I

was able to get from OTTO is not going to work.

It needs a power source to illuminate the green light on the

switch. I suppose I could get someone to

help me tap into a power source but instead I went to Standard Electronics

Supply and purchased an ON/OFF rocker switch.

I installed it in the fuel pump power line and it works just great. I will mount it in the instrument panel below

the ELT switch after I have my DAR inspection and certification. For now it is installed in the line and is

under the map box so the system works like it is supposed to. To turn off the electric fuel pump you must

pull the fuse. That is per Van's

design. So, if you need to power up the

electrical system, in order to not run the electric fuel pump you must pull the

fuse. After the inspection I will be

able to turn the pump on or off from the instrument panel. I also framed the airshow poster I took down

the other day to install the white board.

I had a gold colored frame I had purchased years ago. I went to Rueles and purchased a piece of

glass a some red matt board. While at

the hangar I put it together. I need

some picture hanging wire and I will be able to hang it in the hangar. Maybe I can do so tomorrow.

After that I tackled the fuel tank. I used my holesaw to make a hole for the

Moller fuel gauge. After cutting the

hole I used the reinforcing ring to layout the screw holes. I drilled and then deburred all of the

holes. I also drilled a hole for the new

fuel tank vent.

I

used my shop vac top clean the debris from inside and outside the tank. I then began drilling out the rivets in

preparation for installing the forward lower corner tank reinforcement plates

called out in the fuel tank service notice. It is a real challenge to get the rivets

drilled our correctly. If the mandrel is

still in the rivet it doesn't drill very well.

These are solid back blind rivets so the mandrels can't be punched out

very easily. So far I have been able to

get them out. Now the challenge is

removing the Pre-Seal from the inside corners of the tank. I really gooped them up when I built the tank. Now I am paying the price for doings such a

good job.

I turned my

attention to the stabilator tips. I

finalized the layout and drilling of the left tip. I bent the tabs on the right tip bracket and

attached it to the stabilator. I then

test fit the right tip. It fits pretty

well.

I went through the same layout procedure on the

right tip because it seemed to work so well on the left tip. I put tape around the stabilator and marked

the centerline of the holes in the tabs onto the tape. I then put tape around the tip and slid it

onto the bracket. I transferred the

marks from the stabilator to the tip. I

then determined the location of the holes and marked them on the layout

lines. I drilled the holes in the tip

and installed it on the bracket with clecoes.

I am impressed with how well the tips fit on both sides. I am planning to have the tips painted with the

Maroon color. I will also have the wing

tips painted Maroon so they wings and stabilator are similar. That is all for today. I will be back tomorrow.

Friday, January 17, 2014

Tank Modification and Stabilator Tips

Today I purchased a white board to install at

the hangar. I decided it would be

helpful to have a list of things I need to be working on. When I arrived at the hangar, I discovered something

about MEK and plastic drinking cups. It seemed

like a good idea at the time to leave the screws soaking in the cup. I learned that is not the case. The bottom of the cut melted and the MEK

soaked into the bench top. The screws

are now fully imbedded in a plastic disk.

Oh well, I have plenty more. I

used my trusty putty knife to remove the cup bottom and screws from the bench

top. I also installed my white board and

added several notes.

While at the hangar I decided to add some

additional clecoes to the right side of the rear window at the turtle

deck. By adding some additional clecoes

the turtle deck and window appear to fit together better.

I then began to turn my attention to the

stabilator tips. I ordered the tips kit over

a year ago. I have decided to prepare them

for mounting so I can have them painted when the airplane is painted later this

spring. The tips are ABS and are

attached to the ends of the stabilator with aluminum mounting plates. I bent the tabs on the mounting plate and

then attached the right mounting plate to the stabilator tip by inserting, but

not pulling 2-of the large blind rivets that came with the kit. I will

have to drill additional holes for 2-of the rivets. I wrapped blued tape along the edge of the

stabilator to mark the location of the attachment holes in the tabs. I test fit the tip. It looks like it is going to fit just right.

I wrapped tape around the tip and transferred

the locations of the holes to the tape on the tip. I also marked the center of each hole on the

tip and drilled one hole to see if it lines up with the hole in the mounting

tab. It lined up just right. I marked the right tip with a piece of tape

inside that says "RIGHT". I

will need to put the same mark on the mounting plate.

Before going to the hangar today I spread a

thin layer of PolyGon on the fuel tank sender plate and the forward face of the

fuel tank. Upon returning home I cleaned

the Pro-Seal residue from the tank and the plate. It all come off and left the parts

clean. I will work on them with a

ScotchBrite pad before any reassembly takes place.

Subscribe to:

Comments (Atom)