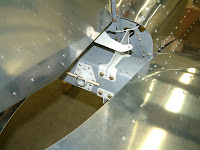

I started the installation of the empennage. I first attached the vertical stabilizer using the called out bolts and the lower hinge assembly. I also installed 3-bolts on the front of the stabilizer. One of the AN3-4A bolts was stripped installing the stabilator brackets so I have ordered some additional bolts. I will install the last bolt after they arrive. Next I installed the rudder. Before doing so I used some Titebond instant glue to glue the washers in place. I glued them per the initial trial fit of the rudder.

After gluing the washers in place I used a sharpened 3/16" dowel to line up the holes. I was able to get the bolts in place and test the swing of the rudder. It seemed to be too close to the vertical stabilizer at the upper left edge.

I removed the rudder and using my angle grinder and a 3M Scotch Brite disk I ground off about 1/16" of the upper edge. The rudder now fits very well. The next step was to install the fiberglass fairings on top of the rudder and the vertical stabilizer. I first fitted the rudder fairing. To do so I had to remove material at the bottom of the fairing so it would fit into the opening. I clamped the fairing to the work bench and used my Dremmel tool to cut the fiberglass. It made a good clean cut. I then fitted the fairing to the top of the rudder and drilled and clecoed it in place.

I then reinstalled the rudder to the vertical stabilizer and began to fit the fairing to the vert stab. It took a bit of cutting, sanding and reshaping but I was able to get the two fairings to fit well together. I then drilled, clecoed and riveted the vertical stabilizer faring in place.