Today is a rare Saturday when I am not working at the Draper Temple. Because of this I took advantage of the day and spent a good amount of time on the airplane. As I was working I had to chuckle a couple of times when some young boys went by on the sidewalk out front and I heard them say to each other, "did you see that airplane?" How cool. It reminds me of when I was a little boy and enthralled by the airplanes I was always around with my Dad.

Today I started by installing the pulleys in the pulley bracket. I ordered a new tool from Sears so I could final drill the holes in the bracket. The tool was to be delivered on Friday. Friday morning I received an email from Sears telling me they had refunded my returned tool. I guess they didn't have one to ship so they just reversed by order. Oh well, I can now chalk up one more reason for thinking the Sears Company is staffed by idiots! Using a ¼" drill bit and a pair of small vise grips I was able to twist the drill thru the holes and open them up to the right diameter. I installed the pulleys and was ready to move on.

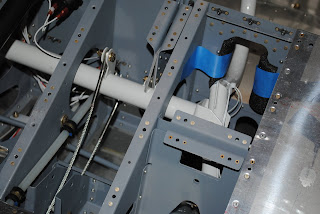

I pulled the stabilator cables thru the rear bulkhead and safety wired them so they would not be pulled back as I connected them under the fuel tank floor. All of the cables are now in the fuselage and thru the rear bulkhead.

Next I installed the vertical stabilizer and rudder so I could mark and cut the rudder control links. To do so I moved the wings out onto the driveway and turned the fuselage sideways in the garage.

The instructions say to center the rudder and clamp the cable links to the rudder control horns. To be sure the rudder is centered and remained centered I clamped to aluminum yard sticks to the tail cone so I could make sure the rudder is centered.

After clamping the cable links to the rudder control horns and making sure the rudder was centered I marked the links. I removed the links from the cables and took them into the shop. Using the links as guides I marked them for the length and to drill the holes. I lined up 2-links and installed an AN3 bolt thru the hole then clamped them together. Using the drill press I drilled a #30 hole thru the links and then final drilled them with a #12 bit. I did the same with the other set of cable links. Next, I clamped them in the vise and using a hack saw, but them to length. One set of links is shorter than the other. I used the bench grinder to round the ends of the links and then cleaned them up with the Scotch Brite wheel. I then installed them on the rudder control cables as instructed. I then installed the links to the rudder pedal arms. I had to turn the fuselage on its side once again in order to reach the rudder pedal arms. I just could not reach them otherwise.

Next I temporarily installed the horizontal stabilator.

In order to be able to install the barrel connectors on the stabilator cables I put stings on the ends of the cables. I also put strings on the ends of the rudder cables. They can now be retrieved if they are inadvertently pulled thru the rear bulkhead. With the fuselage on its side I was able to reach thru the inspection holes in the bottom of the fuselage and pull the stabilator cables together. I installed the brass barrel (threaded connector) onto one of the cable ends. I then attempted to start the other end of the cable to the opposite side of the barrel. Of course the worst thing that could happen did. The barrel slipped out of my fingers and fell thru the lightening holes in the longitudinal ribs. It ended up out of sight. I could not get my hands and arms far enough through the holes to be able to feel the barrel. I turned the fuselage back upright and rolled it over the other way to see if I could get the barrel to roll out of the space it was in. No dice! I spread some packing pads on the floor and laying on my back I attempted to find the part. The barrel is made of brass so I could not use my magnet tool to retrieve it out of the space. Finally, by tapping the aluminum skin on the bottom of the fuselage I was able to locate the barrel. It was on the right side of the fuselage in the small space behind the landing gear attachment point. There is a small hole into the space in the landing gear attachment location. By using my small inspection mirror and by shining a small flashlight into the space I was able to see the barrel. It was just out of reach inside the narrow space at the right bottom edge under the wing. I considered cutting a hole in the skin to retrieve the part. Of course that would necessitate a repair and that did not sound like something I would like to do.

I continued to try to get to the part. I used masking tape to tape the flashlight to the adjacent ribs so it would shine into the space. I then taped the inspection mirror in place so I could observe the barrel without holding these tools. Next I used my claw tool to reach thru the small hole while looking thru the mirror. After several unsuccessful attempts I was able to grab the part with the little claw. As I attempted to pull it out it slipped and fell back into the space. RATS!! I re-taped the light and mirror so I could see the part and tried again. This time, after another untold number of attempts I was able to grab the part and with a lot of gentle maneuvering I was able to pull the part out of the space. I installed the 2nd barrel into the stabilizer control cables. Because this is only a temporary installation of the stabilator I will have to adjust the cables to the proper tension after the stabilator is permanently installed. I removed the stabilator and vertical stab and returned everything to its storage space. Next I start on the canopy.