I finally installed the 2-corner covers at

the main landing gear legs on each side of the fuselage. I cut the pieces apart on the band saw. I deburred the edges and then riveted them to

the fuselage skin on each side below the main gear legs. I inserted the plastic fill in plugs into the

holes drilled in the bottom skin on each side of the fuselage.

Monday, April 22, 2013

Friday, April 19, 2013

Finish Installation of Landing Gear and Fuel Tank

I slipped the gear leg in place and loosely installed the outboard hold

down bracket. I then installed the

inboard doubler and wear plates. I

installed the bolts and attached the inboard hold down bracket. I then tightened all of the bolts

sequentially until all bolts were seated properly. I then torqued all of the bolts to the proper

torque per the SB instructions.

I reinstalled the flexible duct in the mid

channel by reattaching the cushioned clamps.

I also reinstalled the fuel tank.

I also reinstalled the ELT and the ELT antenna bracket.

The airplane is now sitting back on its own

legs.

Thursday, April 18, 2013

Install Wear Plates and Left Main Gear Leg

This afternoon I put a coat of primer on the

exposed surfaces of the outboard hold down bracket chamfered edges and the wear

plates and doubler plates.

Next I installed the outboard doubler and

wear plates. I used 2-AN5 bolts as

alignment pins and installed the plates with the flat head #10 machine screws

with nuts and washers. I then slipped

the gear leg in place and installed the outboard hold down bracket. I aligned the gear leg and installed the

inboard doubler and wear plates and dropped the bolts through the holes.

I sequentially tightened the bolts until they

were all snug and then used the torque wrench to tighten them. I need to purchase an 8" - 3/8" drive

extension before I can torque the AN6 nut at the inboard hold down bracket. After the center AN6 nut and bolt have been

tightened I will reinstall the brake line and the left gear main reinstall will

be complete.

Wednesday, April 17, 2013

Complete SB 13-4-05 Oil Tank Mount Brackets

This afternoon and evening I completed the

painting and installation of the additional rib on the oil tank mount brackets. I prepped and primed the rib this morning and

I applied a coat of finish paint on the rib this afternoon.

I put the rib in place and installed the

pulled rivets. The modification is not

complete.

SB 13-4-05 Oil Tank Mount Brackets

Today I received the parts to modify the oil

tank mount brackets from Vans. Vans issued

a service bulletin after some cracks were discovered at annual inspections on

some aircraft. A new support rib is to

be installed at the bottom of the oil tank mount brackets. I decided to do the modification now instead

of waiting. This evening I set the new additional

rib in place. I then marked and drilled

the oil tank mount brackets.

Thursday, April 11, 2013

Drill and Prep Wear Plates

Today I continued to work on the Service

Bulletin. I finished chamfering the

corners of the outboard gear attach brackets.

They are now ready to be installed.

I deburred the edges of the outboard doubler plates and the outboard

wear plates. Following the directions in

the SB I installed them under the mid-channel along with the drill template

above the mid-channel.

I match drilled the #30 holes in the drill

template through the mid-channel and the plates below. I removed the drill template and deburred the

holes. I reinstalled the drill template

on the other side and did the same thing.

With the template still in place I final

drilled the holes to ¼". I removed

the template, vacuumed up the drill shavings and relocated the drill template

back to the other side and final drilled the ¼" holes in that side.

Friday, April 5, 2013

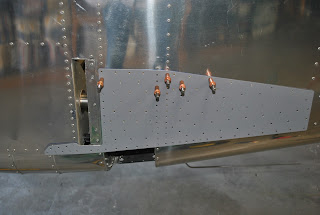

Rivet Side Skin Doublers

First I installed the skin support angles with Cherry Max rivets to the mid fuselage channel. I tapped the spar sleeves back to clear the rivets. I was a real chore to tap them back into place, but I was able to do so. I photographed the skin support angles from above. The photos are not to clear, but they show the angles riveted in place to the channel.

Next I pulled the flush rivets at the bottom

edge of the doublers. All went well.

At this point I pulled the LP4-3 rivets in

the field of the skin doublers.

The last rivets to be pulled were the Cherry

Max rivets attaching the sides to the vertical ribs. All of the rivets for the service bulletin

have been pulled.

I then started to chamfer the corners of the gear

leg hold brackets. I marked the corners

and used my bench grinder to remove the material. It is a long, hot process. I stopped for the evening and will finish

tomorrow.

Wednesday, April 3, 2013

Prep For Skin Doublers

This afternoon I started to prep the airplane

and the doublers for installation. I

started by marking and drilling the holes in the bottom skin. This will accommodate a ¼” ratchet extension

to make installing and torqueing the bolts a little easier. The photos are a bit dark but the holes are

there.

Next I held the skin doubler

to the side of the fuselage and marked its location with a Sharpie. I used a 1/16” drift punch to punch out the

mandrel in all of the rivets to be drilled out.

I then drilled out the rivets on each side of the fuselage. I clecoed the holes as I drilled them to help

keep the skin doubler and the fuselage sides in line. I also drilled out the rivets holding the

side skin support angles attached to the mid fuselage channel.

After drilling out the rivets

on the right side of the fuselage I prepped and primed the doubler skins and

the side skin support angles. I deburred

the edges and used a Scotch Brite pad and some MEK to clean and prep the

surfaces. I clecoed the primed skin

doublers in place on each side of the.

After drilling I removed the skin doubler and deburred the holes and

cleaned away any drill chips between the layers of aluminum.

I used the microstop counterskink to prep the

small side skin doublers to receive the CS4-4 flush rivets. I then clecoed the doubler skins in place. I also clecoed the side skin support angles

to the ends of the mid fuselage channels.

I am ready to match drill the side skin support angles and then start

pulling the rivets.

Subscribe to:

Posts (Atom)