This evening I

mixed up some Pro-Seal and reassembled the fuel tank. I gathered together the parts and pieces I

would need. I also cleaned all of the

surfaces to receive Pro-Seal with MEK. I

then mixed the Pro-Seal and started making a mess. I also vacuumed out the tank and wiped the

inside with MEK to get all of the debris from drilling holes cleaned up and

removed.

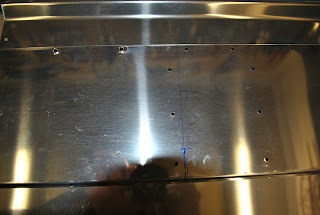

I first sealed and attached the new clip to the top of

the tank to help more fully secure the fuel return line. In the process I put some Pro-Seal along the

tube so it is now glued to the top of the tank along with being held in place

with the clips. I put a smear of

Pro-Seal around the rivet.

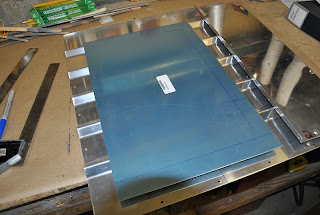

Next I turned my

attention to attaching the clip angles added to the tank and the mounting bar

on the forward end of the tank. The clip

angles were primed and all ready to go.

I smeared some Pro-Seal on the back of each angle and then clecoed them

to the mounting bar. I was then able to

insert the 9-rivets into each of the angles.

I dobbed the rivets in Pro-Seal before inserting them into the holes. Because this modification breaches the bottom

and side of the tank it is critical that the holes and fasteners are sealed properly. I have seen pictures of the final results of

this modification in the RV-12 Forum and the work done by others was not very

pretty. I made an effort to keep the

Pro-Seal from getting all over everything, but it is hard stuff to work with

and stay clean, let along keep the work clean.

After pulling the

rivets I used the syringe filled with Pro-Seal to inject a small dab of sealant

into the top of each rivet. I used a

popsicle stick to put some sealant over the rivets inside of the tank. I then used my gloved finger to spread the

sealant over and around the rivets. What

a goopy-gooey mess. There should not be any

leaks. Next I riveted the nutplates back

in place on the mounting bar/clip angles.

The final step was

to reinstall the sender plate support. I

put a layer of sealant on the back of the sender plate and then put some

sealant under the head of each screw.

What a mess. In a week I will

retest the tank for leaks. After making

sure there are no leaks I will repaint the forward end and it will be ready to

install in the airplane. I will then need

to attach the filler tube to the turtle deck skin and the fuel tank portion of the

build will be complete.