I completed the

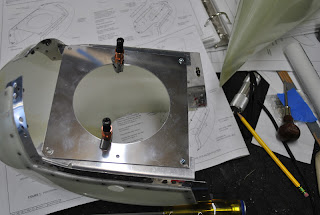

park brake mounting bracket. I bent it

to shape and riveted the nutplates in place.

It will be ready when it is time to install the park brake.

Friday, October 19, 2012

Thursday, October 18, 2012

Future Modifications

I have ordered a universal light cable from McFarlane to control the park brake. I also ordered a black knob with the words PARK BRAKE. I have some thoughts about where to install the control on the instrument panel. I will make the final determination when I am ready to make the installation.

I also put the

ends on the 1/16" tubing for the AOA.

They are connected as the wings are installed. I will drill the wing and install the AOA port

after certification.

Monday, October 15, 2012

Aircraft Assembly

This afternoon I

stopped at the Sutton's in Eagle Mountain and picked up my grandsons, Cameron

and Kaleb. They agreed to help me assemble

the airplane this afternoon. We started

by installing the wheel pants on all three wheels.

Next we installed

the upper fuselage cover over the instrument shelf. After installing the upper cover we installed

the rear window and the turtle deck skins.

These are just clecoed in at this point.

I will permanently install them very soon.

At this point we

moved the airplane onto the driveway and began to install the canopy. We had the canopy in place and lowered it

down. Then just to make sure everything

was OK I raised the canopy. It was

actually to get the camera from inside the cockpit and take a photo. On lifting the canopy, the support arm on the

right side hung-up on the edge of the upper fuselage skin. Lifting the canopy all of the way up bent the

edge of the skin up. We removed the

canopy from the airframe and removed the screws holding the skin in place. With my duck-bill pliers I was able to straighten

out the bent edge. I put a little extra

crease along the edge of the skin so when it is installed it will be tighter to

the fuselage. We reinstalled the screws

and using a file I smoothed the edge of the skin. After reinstalling the canopy we confirmed

that it goes up and down without any interference.

Our next step was

to install the wings. We installed the

left wing and then the right wing. I will

need to pull the wings into place when I install them the final time. Right now it is difficult to install the spar

pins without a huge amount of effort.

Grandma

came out to check our progress.

Next we installed

the empennage. We didn't hook up the control cables, but I know they

work.

Grandma came out

again and the boys encouraged her to take a turn sitting in the cockpit. She was laughing and smiling the whole time so

I guess she liked it. I am going to go

up to MATCO Mfg in Bountiful and purchase their parking brake valve. I am planning to install it in the tunnel

where the brake lines pass on their way to the center section. I will buy the valve from MATCO and a actuator

cable from McFarlane. They make one labeled

'PARK BRAKE.' Of course the park brake

will be installed after

certification.

Friday, October 12, 2012

Nose Gear Leg Fairing

This afternoon I

worked on the nose gear leg fairing. The

epoxy is set under the screws. I removed

the leg fairing and clamped the piano hinge assembly inside with large 'C'

clamps.

Then I started

drilling from one end of the hinge and drilled and clecoed each hole on one

side of the fairing. The drilling and

clecoing went fairly well. My drill

battery ran down so I installed another battery and continued to drill and

cleco while I charged spent battery. I

finished drilling the first side and turned the assembly over and drilled and

clecoed the other side. I removed the

clecoes and using my microsink, prepped the holes in the leg fairing for

riveting the hinge in place.

I took the fairing

into the shop where I had clamped my rivet squeezer in the bench vise. One by one I inserted and squeezed the rivets

attaching the hinge assembly to the leg fairing. I also located the attachment point for the

hinge clamp and drilled a hole for the screw.

I reinstalled the fairing on the gear leg using the hinge pin and screws

to hold it in place.

I reinstalled the

wheel pants to make sure the gear leg fairing and the wheel pants had the

correct amount of clearance. I ended up

trimming the lower flange of the leg fairing to allow the proper clearance at

the top of the wheel pants. There has

been considerable discussion and issuance of SB's concerning the attachment of

the main gear legs to the center channel.

It appears I will be working on these attachment points in the very near

future. A statement from Van's dated

10-12-12 leads me to believe I will be removing the gear to make some structural

modifications. It also looks like I will

be installing some fuselage skin doublers at the wing roots. Someone said, once a builder always a

builder. I guess that is true.

Nose Gear Leg Fairing

I started working

on the nose gear leg fairing. I started

by cleaning up the excess resin material at the bottom inside edge of the

fairing at the joint. There was no way

to make the hinge assemble lay flat in this 'V' because of the excess blobs of

resin. I used the Vixon file and a sanding block to remove the excess material

and made the inside surface flat so the hinge can be installed.

I used the angle

grinder with a flat sanding disk and the sanding drum to remove the fiberglass

to the scribe lines at the top and lower end of the fairing. I slipped the fairing over the nose gear leg

and clamped it in place. Using ¾"

nuts attached to a piece of string I installed a plumb line and checked to be

sure the fairing was lined up properly.

I also drilled the lower flange on the fairing and installed 3-clecos to

hold things in place. I put a strip of

masking tape on each side of the fairing and using a framing square I marked

the tangent location on each piece of masking tape. I measured and marked the screw location on

each piece of tape then drilled a #30 hole through the fiberglass fairing into

the gear leg. I used an 8/32 tap to tap

the holes in the gear leg. I put a piece

of tape around the gear leg covering the drilled and threaded holes. I rein stalled the fairing over the gear

leg. I mixed some epoxy resin with some

glass beads and put eh mixture into a large syringe. I injected the epoxy mixture through the

holes in the fairing to form a puddle of epoxy on the tape on each side of the

gear leg. I then installed wax coated

screws to hold the fairing in place while the epoxy sets.

I then prepped a hinge section for

installation inside of the fairing. I

marked each half of the hinge assembly for drilling. I also fabricated a hinge pin with a 1"

section of hinge with a nut plate installed.

I finish the fairing fabrication tomorrow, after the epoxy has

completely set.

Tuesday, October 9, 2012

Nose Wheel Fairing

This afternoon I

set up the work table in the garage and started to install the nose wheel

fairing onn the nose wheel. I removed

the nose wheel and drilled out the ¼" hole to 5/16" and installed the

bolts, nuts and washers for the tow bar attachment. I used the microstop to countersink the rivet

holes on top of the wheel fork then riveted the nutplates in place.

I re-installed the

pants on the nose wheel and checked to be certain the fairing clears the nose

wheel strut and the it also clears the tire by at least ½". I need to start work on the nose gear strut

fairing.

Monday, October 8, 2012

Nose Wheel Doublers

This afternoon I

installed the doublers on the wheel mounting brackets. This is because of a Service Bulletin issued

by Vans. Inspections of flying RV-12's

has shown cracking of the nose wheel mounting brackets. This is to correct and prevent that problem. I installed the aft half of the nose wheel

pants and marked the location of the mounting brackets on the rill

template. I removed the aft portion of the

pants then clamped and drilled the brackets.

Next I went into

the shop and deburred the holes and deburred the edges of the doubler

plates. I attached the doublers to the

mounting brackets and drilled all of the #40 rivet holes. I deburred the holes and then dimpled the

interior holes along the edge of the brackets.

I also countersunk the corresponding holes in the doubler plates. Next I riveted the doublers to the brackets

using the rivets provided with the kit.

I then temporarily put the forward half of the pants on the nose wheel

to see how it fits. It looks good. I will remove the wheel and install the tow-bar

bolts and washers and install the nutplates.

Wednesday, October 3, 2012

Nose Wheel Pants Continue

This afternoon I stopped at Home Depot and purchased

some #8/32 screws and nuts. I set up my

work area in the garage and started to work on the nose wheel pants again. I used my angle drill to match drill the

screw attachment hole in the aft half of the pants. As I match drilled a hole from inside of the

pants I installed a #8 screw and nut to hold it in place. Working hole by hole and screw by screw I was

able to complete the task. I then mixed

some epoxy and glass beads to spread between the splice plates and the inside

edge of the forward half of the pants. Per

the instructions I put masking tape on the exposed part of the splice

plates. I removed the splice plates and

roughed up the exposed edge of the splice plates and the contact area inside of

the forward section of the pants.

I spread a thin

layer of the epoxy mixture on the splice plates and then clecoed and riveted

them to the forward pants. I then

clecoed the support brackets to the splice plates to confirm they fit properly.

Next I riveted

them in place along with the required nut plates. I also attached the drill template to the support

brackets.

Subscribe to:

Comments (Atom)