Today I worked on several different projects.

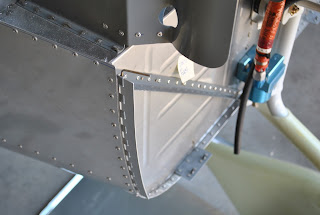

I worked on the firewall stiffener. I

clecoed the stiffener angle and the spacer piece to each other. I then match drilled the #40 holes into the

stiffener angle. I removed the clecos

and cut the spacer into sections by removing the unneeded material. I then used the microstop to prep the spacers

to be riveted to the stiffener. I riveted the pieces together.

I then started to remove the gascolator

bowl. I had to loosen a machine screw

the firewall. After removing 3-of the

4-screws holding the gascolator bowl in place I determined it was not

necessary. I replaced the screws and

installed safety wire. I then drilled

out the rivet in the firewall below the gascolator. I clecoed the end of the stiffener angle to

the firewall below the gascolator. I moved

it into place diagonally on the firewall.

I drilled the upper most hole into the firewall.

I then drilled and clecoed the stiffener to the firewall, starting

at the center of the stiffener. I

installed a cleco in every other hole to

hold the stiffener in place. After drilling all of the

holes I removed the stiffener and deburred the firewall. I then clecoed the stiffener back in place on

the firewall and installed the rivets. I

then began to consider the installation of the side skin stiffeners on the left

and right side of the fuselage. After

removing the sidewall upholstery and considering the potential benefits I

decided not to install these stiffeners at this point in the build. I can always install them at a later date if

I determine they would be of benefit

I

then started to work on the cowling hinges and hinge pins. I cut both sets of side hinges . I then cut the left and right side hinge pins. I prepared all of the required hinge pins by

bending the ends and cutting them to length.

I also ground the ends of the pins and curved them to follow the profile

of the respective hinges.

Next I turned my attention to the engine

cowling. I marked the upper cowling for

the holes to be drilled on each side of the propeller opening. I clamped the sections together and drilled

the inner most holes on each side of the opening. I clecoed the sections together. I also clamped the rear edges together and

checked the fit.

After installing the 4” hinges on each side

of the fuselage engine shelf I clamped the lower cowling in place.

The lower cowl seems to fit pretty well. I am a little concerned about the way it fits

at the lower curve of the fuselage. I am

going to experiment with lowering it 1/16th of an inch on each side

to see if it follows the curve a little better.

If it does I will sand the 1/16th of an inch from the bottom

of the tab on the lower cowling. I am

planning to use some Gorilla tape to hole it in place. I can then lay the upper cowling in place and

see if it fits. If all goes well I will

begin fitting and drilling the hinges.

I clamped one of the side hinges to the lower

cowling. I then laid the upper cowling

in place to see how it looks. It looks

pretty good to me.