Next I held the skin doubler

to the side of the fuselage and marked its location with a Sharpie. I used a 1/16” drift punch to punch out the

mandrel in all of the rivets to be drilled out.

I then drilled out the rivets on each side of the fuselage. I clecoed the holes as I drilled them to help

keep the skin doubler and the fuselage sides in line. I also drilled out the rivets holding the

side skin support angles attached to the mid fuselage channel.

After drilling out the rivets

on the right side of the fuselage I prepped and primed the doubler skins and

the side skin support angles. I deburred

the edges and used a Scotch Brite pad and some MEK to clean and prep the

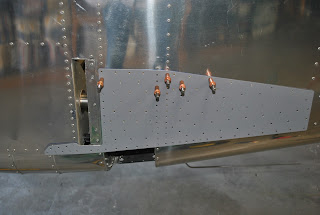

surfaces. I clecoed the primed skin

doublers in place on each side of the.

After drilling I removed the skin doubler and deburred the holes and

cleaned away any drill chips between the layers of aluminum.

I used the microstop counterskink to prep the

small side skin doublers to receive the CS4-4 flush rivets. I then clecoed the doubler skins in place. I also clecoed the side skin support angles

to the ends of the mid fuselage channels.

I am ready to match drill the side skin support angles and then start

pulling the rivets.